Facilities: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| Line 12: | Line 12: | ||

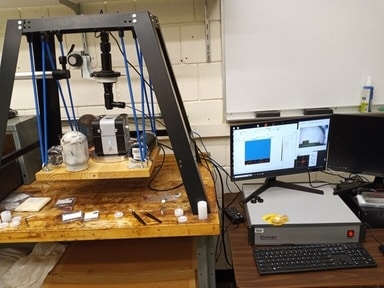

[[File:AFM.jpg|frame|center|Atomic Force Microscope capable of standard AFM, Conducting AFM, | [[File:AFM.jpg|frame|center|Atomic Force Microscope capable of standard AFM, Conducting AFM, Piezo-Force microscopy, Kelvin-probe microscopy]] | ||

| Line 27: | Line 27: | ||

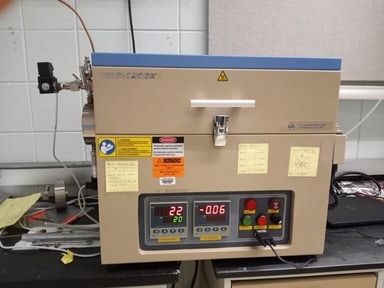

[[File:Img14.jpg|frame|center|Optical & E-beam Lithography systems | [[File:Img14.jpg|frame|center|Optical & E-beam Lithography systems for fabricating nano/micro-scale devices]] | ||

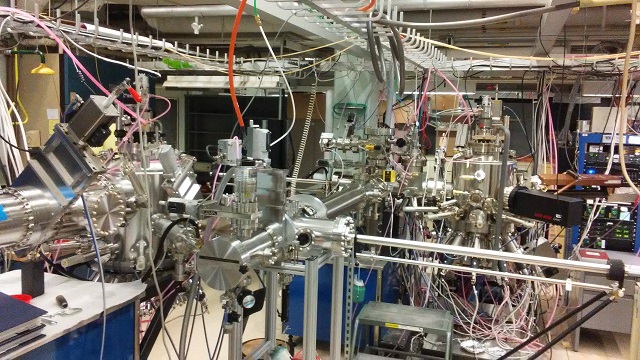

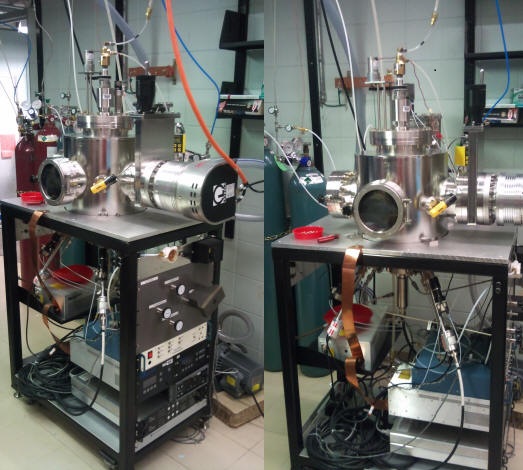

[[File:img3.jpg|frame|center| | [[File:img3.jpg|frame|center|Thermal Evaporator, E-beam Evaporator, and Sputtering chamber for device fabrication]] | ||

Revision as of 15:31, 20 May 2022

Growth

Characterization & Fabrication